Exploring Acoustic Barriers: Effective Solutions for Sound

Introduction

In today’s world, managing sound pollution has become more crucial than ever. Whether it’s in residential, industrial, or commercial spaces, noise control is essential for comfort, safety, and overall well-being. Acoustic barriers are highly effective products designed to reduce or block noise transmission, offering a wide range of applications across various sectors. In this article, we will dive into the significance of acoustic barriers, the different types of barrier products, and their diverse uses in multiple industries.

What Are Acoustic Barriers?

Acoustic barriers are materials engineered to reduce the passage of sound between spaces. These products are commonly used in environments where noise levels must be controlled to create a more comfortable and quieter atmosphere. Acoustic barriers work by either absorbing or reflecting sound waves, preventing them from traveling from one area to another. These solutions are essential in applications where excessive noise can be a health concern or a hindrance to productivity.

There are different forms of acoustic barriers available, each designed to meet specific soundproofing needs. From flexible sound-insulating sheets to heavy-duty materials that reduce vibrations, acoustic barriers offer a comprehensive range of solutions for sound control.

Types of Acoustic Barrier Products

Acoustic barrier products come in many forms, each offering unique properties for various applications. Let’s explore some of the most popular barrier options available today.

1. Polymeric Acoustic Barriers

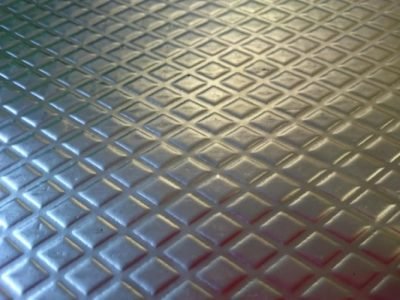

Polymeric barriers, like the C03 (1.4mm) and C09 (2.5mm), are made from low-density vinyl combined with natural materials. These barriers are designed to provide enhanced sound insulation, especially for existing panels made from materials such as metal, wood, or plastic. Polymeric acoustic barriers are highly effective in combating resonance issues, such as coincidence dip, in lightweight panels like plywood and hollow-core materials.

These barriers can be applied directly to surfaces to significantly improve their soundproofing capabilities. Their flexibility and ease of installation make them a preferred choice for many industries looking to upgrade their existing materials without the need for complete replacement.

2. Bitumen PE Foil Covered Acoustic Barriers

The C022 (3mm) and C023 (5mm) are bitumen-based acoustic barriers that come with a black PE foil covering. The bitumen layer helps to dampen sound, while the PE foil protects the bitumen from contamination and facilitates bonding to other surfaces. These barriers are especially effective in applications that require flat sound insulation, such as in automotive panels, industrial machinery, and white goods.

The self-adhesive backing of these barriers makes them easy to install, offering a hassle-free solution for various industries. The PE foil also helps prevent the seepage of oils, keeping the surface clean and tidy while ensuring lasting performance.

3. Bitumen Aluminium Acoustic Barriers

Bitumen aluminium barriers, like the C024, are designed to withstand high-temperature environments. These barriers consist of a dense layer made of bitumen, polymers, and mineral fillers, all covered with an aluminium foil for extra protection. The C024 is ideal for soundproofing applications in areas exposed to heat, such as engine blocks in automotive and agricultural machinery.

These barriers are highly effective at reducing noise and vibration in engines, construction vehicles, and marine equipment, where both thermal insulation and sound control are essential.

Key Applications of Acoustic Barriers

Acoustic barriers find applications in a variety of industries, where controlling noise is critical for efficiency, comfort, and safety. Let’s examine some of the key sectors that benefit from these products.

1. Automotive Sector

In the automotive industry, noise reduction is a key factor in ensuring a comfortable driving experience. Acoustic barriers are applied to vehicle components like doors, engine blocks, and panels to minimize road noise, engine noise, and vibrations. These barriers help improve the overall sound quality inside vehicles, making them quieter and more enjoyable to drive.

Automotive manufacturers use acoustic barriers to enhance the sound insulation properties of lightweight materials, ensuring that even vehicles made with composites or thin panels can still meet soundproofing standards.

2. Household Appliances

In the realm of home appliances, products like refrigerators, dishwashers, and washing machines can generate significant noise during operation. Acoustic barriers are used inside these appliances to reduce noise and vibration, improving the user experience. These materials are typically applied to internal panels and components, helping to dampen the noise produced by motors, compressors, and moving parts.

By incorporating acoustic barriers, manufacturers can offer quieter appliances that enhance the quality of life for consumers.

3. Lift and Elevator Systems

Elevators are another area where acoustic barriers are crucial for noise control. These barriers help reduce the sound produced by the elevator’s machinery and movement, ensuring a quieter ride for passengers. In addition to enhancing comfort, reducing elevator noise also contributes to the safety of the system, preventing potential disruptions caused by high sound levels in busy areas.

4. Construction and Agricultural Equipment

Construction and agricultural vehicles, including excavators, tractors, and cranes, often operate in noisy environments, putting workers at risk of hearing damage. Acoustic barriers are used in the cabins and engine areas of these machines to reduce the noise generated during operation. These barriers improve operator comfort and reduce the risk of hearing loss caused by prolonged exposure to high noise levels.

In construction vehicles, acoustic barriers also help reduce vibrations that can affect the integrity of the machinery and surrounding structures.

5. Pipe Insulation

Acoustic barriers are also used to insulate pipes in industrial settings. In large facilities where fluid flow through pipes can generate significant noise, these barriers help control the sound levels and prevent it from affecting nearby areas. This is especially important in industries like oil and gas, where pipes are frequently in motion and produce loud noises during operation.

By combining acoustic barriers with traditional pipe insulation, companies can reduce both thermal loss and noise levels, creating a more efficient and quieter environment.

Advantages of Acoustic Barriers

Incorporating acoustic barriers into various applications offers numerous benefits. Below are some of the key advantages these products provide:

1. Improved Noise Control

The primary benefit of acoustic barriers is their ability to significantly reduce noise transmission. By adding these products to vehicles, machinery, or buildings, companies can create quieter, more comfortable environments, reducing the overall impact of noise pollution.

2. Enhanced Comfort and Safety

Reducing noise exposure is crucial for maintaining comfort and safety in many workplaces. Acoustic barriers help to create safer environments by minimizing the risk of hearing damage from continuous exposure to high noise levels. This is especially important in industries like construction, manufacturing, and automotive, where workers are frequently exposed to loud machinery and engines.

3. Vibration Reduction

Acoustic barriers also provide vibration-dampening properties, helping to reduce the impact of vibrations caused by machinery or heavy equipment. This not only improves operator comfort but also extends the lifespan of equipment by preventing the wear and tear that can result from constant vibrations.

4. Thermal Insulation

Certain types of acoustic barriers, such as bitumen aluminium barriers, also offer thermal insulation benefits. These products help to reflect heat, providing additional energy efficiency in environments where temperature control is important. This feature is particularly useful in applications like automotive manufacturing and industrial machinery.

5. Customization and Versatility

Acoustic barriers are highly customizable, allowing them to be tailored to specific needs and applications. Whether it’s die-cutting the material to fit curved surfaces or combining different barrier products to achieve optimal results, these products offer flexibility to meet diverse soundproofing challenges across various industries.

Read Also: Why Wedding Planning Services Are Worth the Investment

Conclusion

Acoustic barriers play a critical role in sound insulation and noise control across a wide range of industries. By preventing sound transmission and reducing vibrations, these products enhance comfort, safety, and efficiency in workplaces and vehicles. From automotive and construction sectors to household appliances and agricultural machinery, the application of acoustic barriers offers significant benefits that cannot be overlooked.

If you’re looking to improve noise control in your industry, acoustic barrier products are the solution you need. By working with experienced manufacturers like Acoustafoam, you can find the right barrier products to meet your specific requirements and achieve a quieter, more efficient environment.