How to Calculate and Install the Right-Sized Conduit for Commercial Wiring

Choosing and installing the right-sized conduit for commercial wiring is an essential part of any electrical installation. The conduit not only protects the wiring but also ensures the safe and efficient operation of the electrical system. Properly sizing and installing conduit ensures that the wires inside the conduit can fit comfortably, remain well-organized, and function without risk of overheating or damage. In a commercial setting, where wiring systems tend to be larger and more complex, it is especially crucial to follow the correct procedures to prevent hazards, maintain compliance with codes, and ensure that the electrical system operates smoothly. A commercial electrician plays a key role in calculating the right-sized conduit and ensuring that it is installed correctly.

Importance of Correct Conduit Sizing

Conduit sizing is not just about fitting the wires inside. The right conduit size ensures that there is adequate space for heat dissipation, allows easy installation and future modifications, and prevents excessive bending of wires, which could cause wear and tear. Moreover, improper sizing can lead to several issues, including overheating, difficulty pulling wires, and potential damage to both the wires and the conduit itself.

In commercial installations, where the load and complexity are greater, it is essential to ensure that the conduit is large enough to accommodate all cables, including power, control, and communication lines. Furthermore, conduit sizing must comply with National Electrical Code (NEC) regulations, which provide guidelines for proper wire protection and management.

Key Factors to Consider When Sizing Conduit

There are several factors that a commercial electrician must consider when selecting and sizing conduit for commercial wiring installations:

1. Wire Gauge and Number of Wires

The size of the wires being used will directly influence the conduit size. Larger wires or cables require larger conduit to accommodate their size. Additionally, the number of wires being run through the conduit affects the overall conduit capacity. The more wires in a conduit, the larger the conduit needs to be to allow sufficient space for each wire.

2. Type of Conduit

Different types of conduit are available for various applications, including metal conduit (e.g., EMT, RMC), PVC conduit, and flexible conduit. The choice of conduit material will affect the internal dimensions of the conduit, influencing the final size needed for a commercial installation.

3. Conduit Fill Capacity

The NEC provides guidelines for how much of the conduit’s internal space can be filled with wires. According to the NEC, the conduit should be no more than 40% full for one wire, 31% for two wires, and 40% for three or more wires. This ensures that the wires have sufficient space for heat dissipation and future expansion.

4. Bending Radius and Installation Space

Conduit sizing is also influenced by the allowable bending radius of the conduit. Tight bends in conduit can damage cables and make wire pulling more difficult. The correct conduit size provides enough room for the wires to travel smoothly through the conduit, avoiding damage from excessive bending.

5. Conduit Length

The length of the conduit run will impact the installation process. Longer runs may require larger conduits or the addition of pull boxes at certain intervals to ensure that wires can be pulled without too much resistance. A commercial electrician must account for this when determining the conduit size and the best layout for wiring.

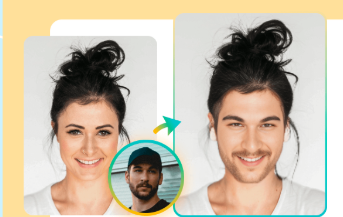

Read also: How AI Face Swap Technology Is Revolutionizing Video Tutorials

How to Calculate the Right-Sized Conduit

A commercial electrician uses several methods to calculate the appropriate conduit size, typically following the NEC guidelines. Here’s a step-by-step process:

Step 1: Determine the Total Cross-Sectional Area of the Wires

To calculate the conduit size, the first step is to determine the total cross-sectional area of the wires that will be placed in the conduit. This is done by referring to the wire’s gauge and its corresponding area. For example, a 14 AWG wire has a different cross-sectional area than a 6 AWG wire. The total area for multiple wires is simply the sum of the individual areas.

Step 2: Select the Conduit Type and Material

The next step is to select the type and material of the conduit being used. For example, EMT (electrical metallic tubing) has different internal dimensions compared to PVC conduit. A commercial electrician will choose the material based on the specific requirements of the project, such as environmental factors, load-bearing needs, and ease of installation.

Step 3: Apply NEC Conduit Fill Guidelines

The NEC sets fill capacity limits for various types of conduit. The total cross-sectional area of the wires should not exceed the specified fill limit for the chosen conduit. A commercial electrician will consult the NEC’s fill tables to determine the maximum allowable wire fill based on the type and size of the conduit.

For example, if you are using a 2-inch EMT conduit, you would need to ensure that the total area of the wires inside the conduit does not exceed the maximum fill percentage set by the NEC.

Step 4: Calculate the Conduit Size Using a Conduit Fill Calculator

Conduit fill calculators, available both online and in NEC guides, can simplify the process of calculating conduit size. These tools calculate the required conduit size by inputting the wire gauge, number of wires, and wire material. A commercial electrician may use these calculators to streamline the process and ensure accurate calculations.

Step 5: Double-Check for Future Expansion

It is also wise to size conduit with future expansion in mind. If you anticipate adding more wiring in the future, it may be beneficial to choose a larger conduit. This will save you from having to replace or resize the conduit at a later date, making it easier to upgrade your electrical system without significant downtime or cost.

Steps to Install the Right-Sized Conduit

Once the appropriate conduit size has been calculated, the installation process begins. The following steps outline how a commercial electrician would typically install conduit in a commercial setting:

1. Plan the Layout

Before installation, the commercial electrician will plan the conduit layout. This includes determining the path the conduit will follow, identifying any obstacles, and ensuring that the conduit is properly routed to meet code requirements. The layout will also take into consideration any bends, which should be kept to a minimum to ensure easy wire pulling.

2. Cut and Prepare the Conduit

The next step involves cutting the conduit to the required lengths and preparing it for installation. A commercial electrician will use a pipe cutter or hacksaw to ensure a clean, straight cut. The edges will then be smoothed to prevent damage to the wires during installation.

3. Install the Conduit

The electrician will secure the conduit in place, ensuring that it is properly supported along its entire length, especially for longer runs. Conduit supports are typically installed every 3 to 10 feet, depending on the type of conduit used. Bends should be made using proper bending tools to maintain the integrity of the conduit and avoid sharp angles that could damage the wiring.

4. Pull the Wires

Once the conduit is installed, the electrician will begin pulling the wires through. Care is taken to avoid excessive pulling force, which could damage the wires or cause them to kink. In longer runs, pull boxes may be used to provide a break in the conduit and assist with wire management.

5. Secure the Conduit and Terminate the Wires

Once the wires are pulled through, the electrician will secure the conduit to the electrical boxes and terminate the wires at their appropriate connections. Proper grounding and bonding of the conduit will also be ensured to maintain system safety.

Conclusion

Properly calculating and installing the right-sized conduit for commercial wiring is an essential task that ensures the safety, efficiency, and longevity of the electrical system. A commercial electrician plays a vital role in calculating the conduit size, selecting the appropriate material, and installing the conduit according to code requirements. By following the proper steps and guidelines, commercial electricians ensure that electrical systems are secure, reliable, and capable of handling the load and potential future upgrades.